Control manufacturers normally preset the pressure regulator in natural gas valves at the time of manufacture so that natural gas units are fired at this 3 5 in w c.

Typical manifold pressure for propane gas furnace.

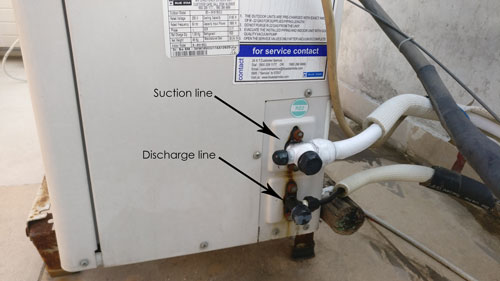

Gas manifolds furnace gas manifolds connect the valve to the main burners and it is important that the proper pressure be present inside the manifold for proper combustion.

Manifold pressure is measured in water column and it has maximum value of 1 psi.

Two types of manometer are water and digital manometers.

Manifold pressure should be set at 3 5 in w c.

Manifold pressure is different from natural gas to liquid propane.

The minimum gas supply pressure must be 1 water column 0 036 psi or 249 pa or 2 5 millibars above the manifold pressure printed on the appliance data plate the maximum gas supply pressure must not exceed 14 water column 0 5 psi or 3487 pa or 34 9 millibars.

Manometer is the device that used to measure pressure.

Only small variations in the gas flow should be made by adjusting the pressure regulator.

When pressure tests are performed on lpg piping typically the system is sealed a pressure gauge is installed and the system is pressurized to 1 1 2 times the maximum design operating pressure of the system or a minimum of 3 psi.

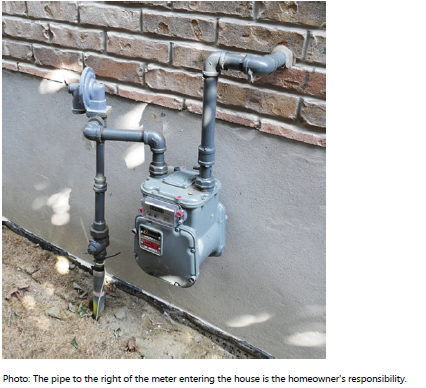

It is testing the building s gas piping and gas appliances for leaks.