The torch applied member of the modified family is marketed as a rubber membrane which is very misleading due to the fact that the modifiers or additives used in the manufacturing formula actually contains no rubber at all.

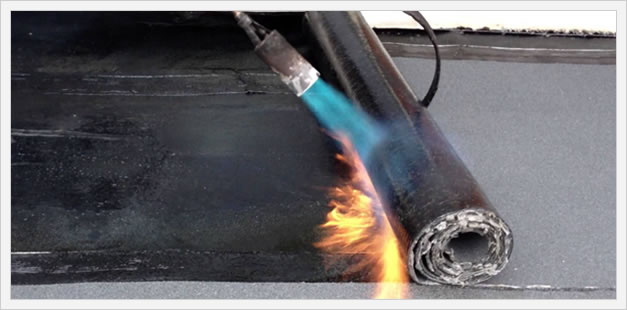

Torch applied rubber roofing.

Torch applied roofing comgn291 updated.

Torch down roof application.

There are several advantages to having a three layer torch down roofing system installed.

App atactic polypropylene uses plastic type modifiers not rubber.

The first polymer used for this purpose is atactic polypropylene app which is a form of plastic not rubber.

Sbs modified bitumen membranes are also flexible and they have a lower melting point than app membranes.

This means that sbs membranes can be used in torch down roofing as well as self adhering and cold processed roofing systems.

1 17 gaf offers an extensive selection of roof guarantees to meet the needs of most building owners.

Sbs is a type of rubber used to create modified bitumen for torch down roofing.

App torch down roofing membranes are flexible and respond well to both heating and cooling.

This roof was installed by commercial roof usa over 14 years ago and as of this writing there are no signs of repair patches.

Advantages of three layer torch down roofing.

Torch down roofing is made of a rubberized asphalt material that is melted to the roof of a home using a torch.

This roof is located on 819 westport rd east westport connecticut.

Modified bitumen torch down rubber roofs are heat welded at the seams.

The following guarantees are available for use with selected gafglas ruberoid and liberty roof systems when installed by an eligible gaf factory certified contractor.

Manufacturing torch down roofing requires modifying or mixing the bitumen with a polymer.